OPERATIONAL PROCESS AND INFRASTRUCTURE

The factory is situated on 6 acres of land in Edathala Panchayat, Aluva, near Kochi. The location offers excellent connectivity to the seaport and National Highway, facilitating smooth logistics and supply chain operations. We prioritize maintaining high-quality standards to meet and exceed customer expectations. To ensure this, our factory and laboratory are equipped with the most modern equipment and technologies.

Our factory uses advanced and precise machines to carry out every stage of the manufacturing process efficiently and accurately.

The raw material sieving system, equipped with Rotary sieve, Vibrators, and Blowers, ensures initial automated sorting of raw materials upon receipt. Inspection Conveyors are employed for manual sorting at initial stage.

We provide a minimum of 6 hours of soaking for dirt removal and better size reduction.

Size reduction of raw materials is efficiently handled by equipment such as Slab cutter, Twin Screw Pre-Breakers, Hammer Mills, and Shredders. The 18" Dual Drive Creepers facilitate better rubber sheeting and aid in the removal of embedded contamination, enhancing product quality.

Further processing involves optimal filling of crumb rubber into trays at the Crumb Filling Station, followed by drying in a Hot Air Single Layer Dryer, which effectively removes moisture from the rubber to achieve the desired dryness and quality.

Compression of rubber biscuits is carried out using a Twin Chamber Hydraulic Press, which applies specified pressure for uniform density.

The Metal Detector ensures that any metallic contamination larger than 2 mm is identified, safeguarding product purity. Automation, including a PLC Controlled Packaging Line, supports efficient and standardized product packaging.

QUALITY

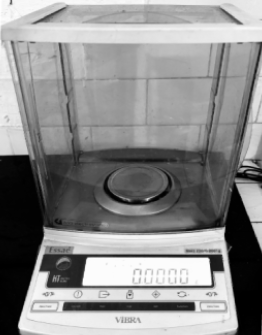

We Edathala Polymers maintains our laboratory equipped with the latest technology and instruments, staffed by skilled and experienced personnel. Our laboratory features essential equipment such as the Mixing Mill, Plastimeter, PRI Ageing Oven, Electronic Weighing Balance, IR Heating Unit, Muffle Furnace, Hot Air Oven, and Nitrogen Testing Apparatus.

This comprehensive array of sophisticated tools enables us to conduct rigorous testing and precise quality control measures. We are deeply committed to quality assurance; every process and test is meticulously performed to ensure our products meet the highest standards of consistency, reliability, and performance. This dedication to quality supports our mission to exceed customer expectations and uphold the integrity of our products.

Our commitment to sustainable manufacturing is underscored by the integration of a Biomass Gasifier, promoting the use of renewable energy within our operations.

This blend of advanced processing technologies and sustainable practices allows us to maintain our production capacity of 12,000 MT of Indian Standard Natural Rubber (ISNR) annually while adhering to rigorous quality and environmental standards.